Nanoparticles / Colloids

Cardiff Diamond Foundry purifies commercial diamond nanopowders as well as fabricating custom diamond nanoparticles from scratch. for details on our recent research see nanodiamond. We also have a comprehensive characterisation facility for particle size, zeta potential, streaming potential pH, conductivity, optical properties, Raman and Photoluminescence.

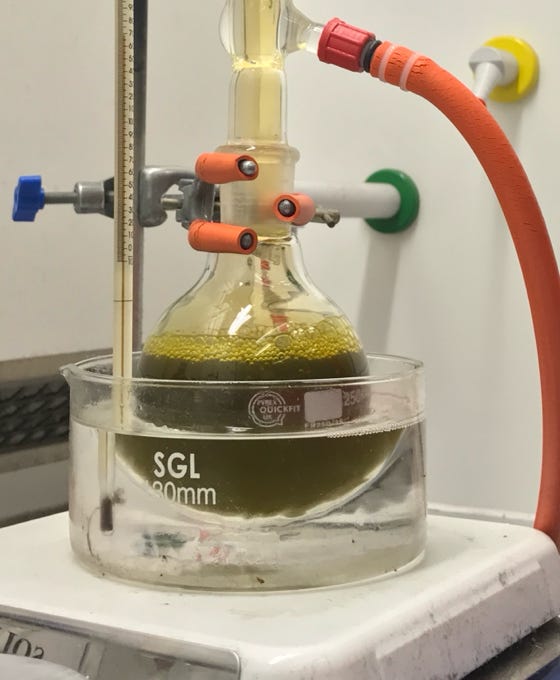

The nanoparticles purification facility includes several high temperature vacuum furnaces with gas options (see furnaces). These are used for surface oxidation, hydrogenation and other gas phase treatments that we have found more efficacious than liquid based approaches. We also have acid reflux setups for HNO3, HCl etc to remove metals and other contaminants.

Dispersal of purified nanodiamond particles can be achieved by a high power ultrasonic probe (Sonics VCX500 500W). We also have a high G refrigerated centrifuge for removing contaminants and large particles. We use a high energy planetary mill (Pulverisette 7 Premium Line) for the milling of bulk diamond films into nanoparticles. Combined with the CVD facilities, the production of custom nanodiamond particles with controlled impurities such as silicon, nitrogen, boron etc is possible.

Left to right: Water cooled high power ultrasonic treatment of nanoparticle colloids; acid reflux (HNO3 in this case) of nanoparticles; 60 KG RCF centrifuge (top) and Pulverisette 7 Premium Line high energy planetary mill (bottom).

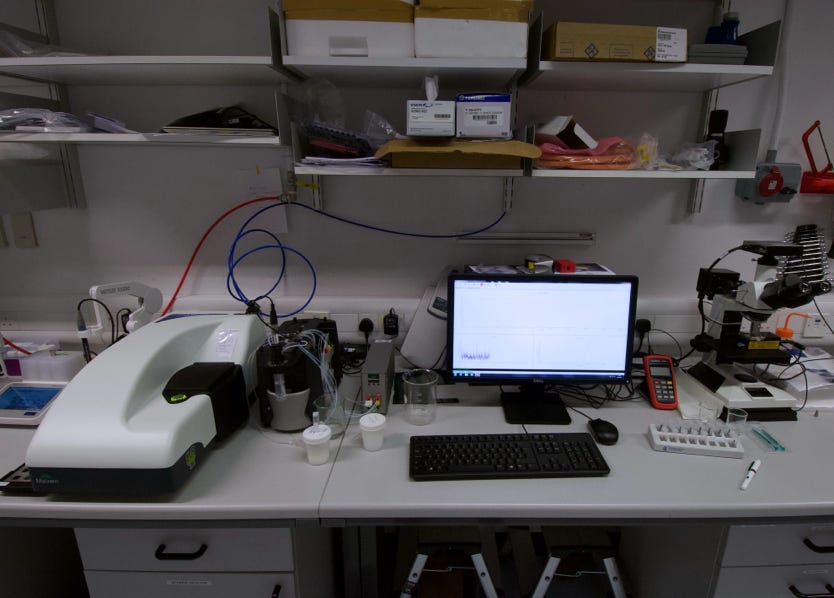

Left to right: Genesys 10s uv-vis spectrometer and Mettler Teledo SevenMulti pH and conductivity meter; Malvern Zetasizer Nano ZS with autotitrator (Dynamic Light Scattering apparatus; Nanosight LM10 for Nanoparticle Tracking Analysis.

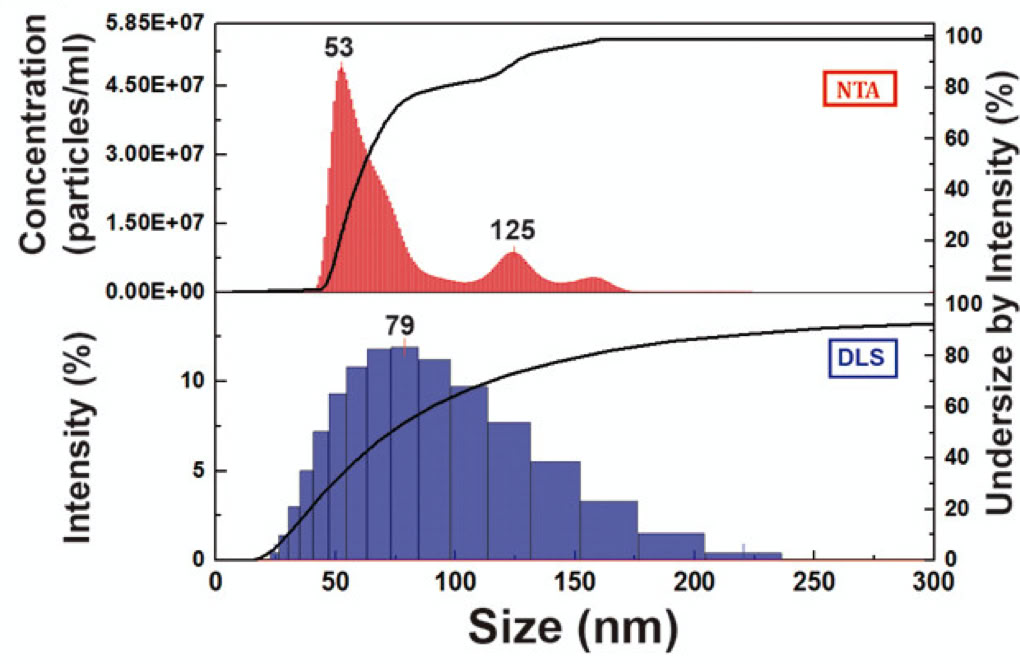

Left: Comparison of Nanoparticle Tracking Analysis (NTA, red) with Dynamic Light Scattering (DLS, blue) of the same sample. NTA is able to distinguish different size distributions within the solution whereas DLS can only see an overall distribution. This is because DLS distributions are skewed by the largest particle size, with particles ten times the size scattering million times more light. NTA tracks individual particles within the solution rather than overall scatter from a solution, see Gines et al, ACS Omega,3 (2018) 16099.

Right: Anton Parr SurPASS 3 electrokinetic analyser. The SurPASS measures surface zeta potential via the streaming potential / current method as a function of pH etc. This allows us to characterise the interface between solutes and solid surfaces, predicting electrostatic attraction or repulsion between particles and surfaces. We have used this to improve nucleation of diamond on various materials such as GaN, AlN, SiN, LiNbO3 etc:

Mandal et al, ACS Omega 3 (2017) 7275 (GaN)

Bland et al, Scientific Reports 9 (2019) 2911 (SiN)

Mandal et al, Nanoscale 11 (2019) 10266 (BN)

Mandal et al, ACS Mat. & Inter. 11 (2019) 40826 (AlN)

Mandal et al, Carbon, 181 (2021) 79 (Ga2O3)